3D Scanning & 3D Printing Technology: Bring Old Objects Back to Life via 3D Scanner & 3D Scanning Reverse Engineering

A Swiss Army knife that has been used for thirteen years suffered severe shell deformation due to high temperature, but it was too precious to discard because of the memories it carried. Traditional repair methods are time-consuming and laborious, but now, with the help of 3D scanning and 3D printing technology, I decided to remake its shell by myself. This is not only a repair, but also an up-close experience with modern technology!

1. Precision Modeling: Reverse Engineering Restores the Original Structure

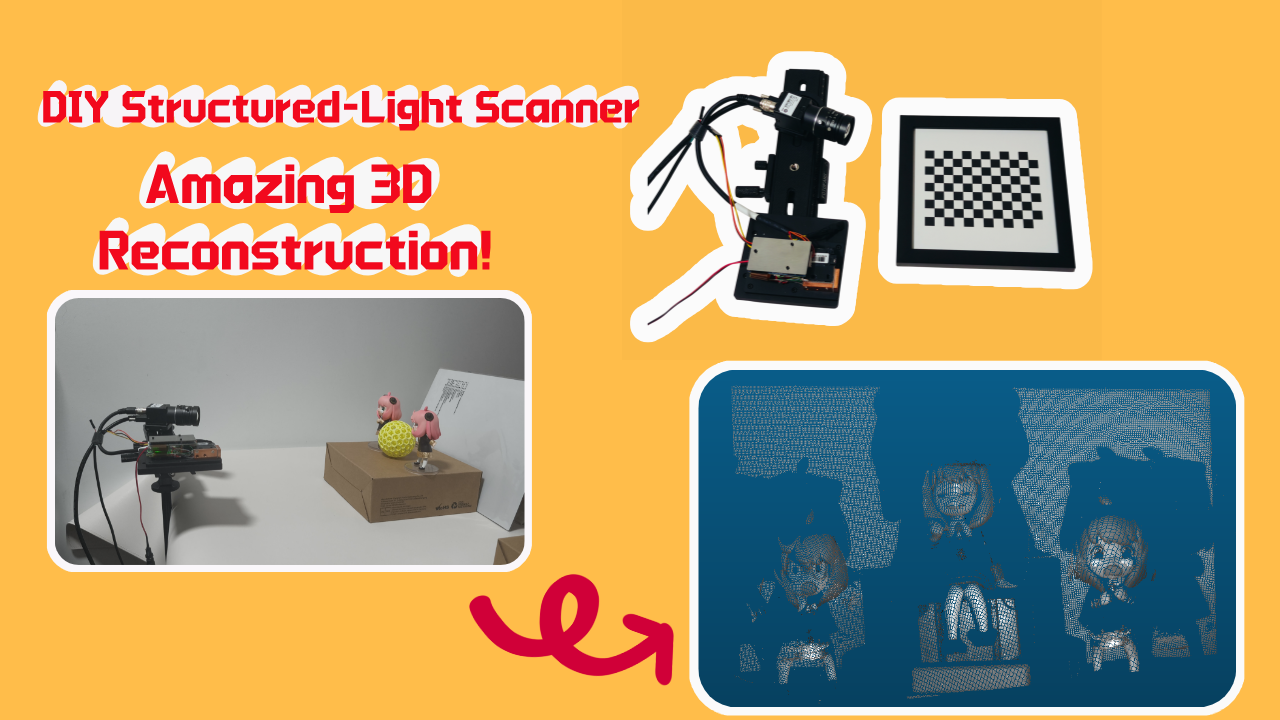

The first step in repair is to obtain accurate 3D data of the shell. This 3D scanner from Xiangxi Intelligent boasts high precision and fast scanning speed, capable of capturing every detail on the surface of an object. By scanning the old shell from multiple angles with the scanner, the system generates 3D point clouds in real time and automatically splices them into a complete model. This step is precisely the key to reverse engineering — converting physical objects into editable digital models, laying a solid foundation for subsequent repair and design.

Xiangxi Intelligent’s scanner supports high-resolution scanning. Even if the shell is partially irregular due to deformation, it can fully capture its geometric features. After several rounds of scanning and data alignment, I obtained a clear STL file. The entire process fully demonstrates the powerful capability of 3D scanning technology in physical object digitization.

2. Optimization and Modeling: Reverse Engineering Enables Repair and Personalized

After scanning, the next step is to repair and design based on the scanned data. I used modeling software to repair the scanned model: filling in gaps, correcting deformed areas, and generating STP files usable for manufacturing. This step is also an important part of reverse engineering — restoring and even optimizing the physical structure in a digital environment.

The precise model obtained through scanning makes subsequent modifications and adjustments more free and efficient. The high-quality model output by Xiangxi Intelligent’s scanner greatly reduces the manual correction work during the modeling process, allowing me to focus more on optimizing the shell’s performance and appearance.

3.Rapid Prototyping: 3D Printing Technology Realizes Physical Reconstruction

After modeling is completed, the next step is to turn the digital model into a physical entity. Import the repaired STP file into 3D printing software and start printing the new shell. The advantage of 3D printing technology lies in its speed, flexibility, and suitability for small-batch customization. During the printing process, the layered molding method ensures the integrity of the shell structure, and the holes and buckles perfectly match the original components.

compared with the old shell, the first printed shell fits very well. Through 3D printing, we can not only replicate the original structure, but also choose materials and colors, and even carry out lightweight design. This is the charm of the combination of 3D scanning and 3D printing — from scanning to finished product, the whole process is digital, controllable and adjustable.

Finally, I polished the surface and optimized the chamfer of the printed part, and assembled it onto the main body of the Swiss Army knife. A “reborn” Swiss Army knife not only regains its function, but also carries new meanings. If you also have old items that are damaged but too precious to throw away, you may wish to try 3D scanning and 3D printing. With the help of Xiangxi Intelligent’s 3D scanner, realize precise modeling through for rapid manufacturing — making it possible to revitalize old objects.

Whether it is repairing precious old items, customizing personalized parts, or optimizing product design, 3D scanning, 3D scanner, 3D printing and reverse engineering are becoming indispensable core forces, bringing more possibilities to our life and work.

Welcome to visit our Alibaba homepage: https://xx3dtech.en.alibaba.com/ to know more about our 3D scanner. No matter the scanner you would use for, there is always a scanner that can meet your needs.

Subscribe Our Channel

XX-3DTECH (Xiangxi Intelligent technology) is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.