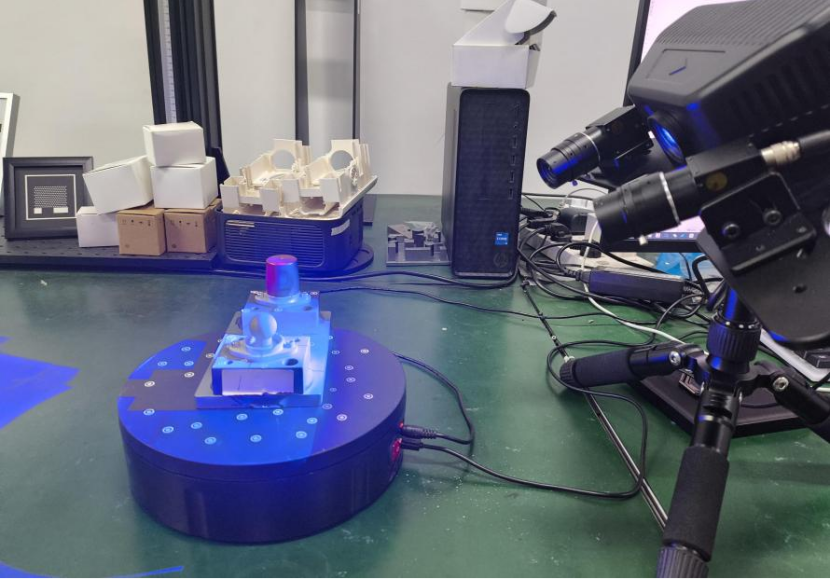

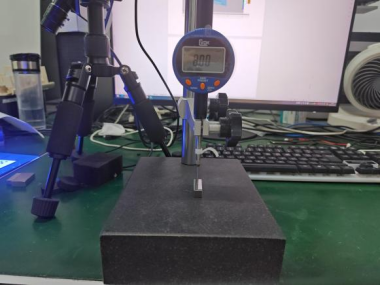

In today’s fast-evolving digital world, industrial 3D scanners have become essential tools across industries — from advanced manufacturing and quality inspection to cultural heritage preservation and even medical applications. But did you know that one small factor can make a huge difference in your scanning results? Yes — I’m talking about the humble but powerful 3D scan spray.

Why Should You Care About 3D Scan Sprays?

Think of your industrial 3D scanner as a high-tech eye. To capture every fine detail, it needs a clear, uniform surface to read. That’s where a 3D scan spray steps in — acting like a pair of special glasses that help your scanner “see” with maximum precision.

Without the right 3D scan spray — or the right spraying method — you might end up with poor data, measurement deviations, and inaccurate 3D models. Not ideal if you’re scanning precision parts or priceless artifacts!

Let’s Break It Down: What’s Inside the Spray Matters

Not all 3D scan sprays are made equal. Their chemical makeup and how they behave on the surface directly impact 3D scanner accuracy.

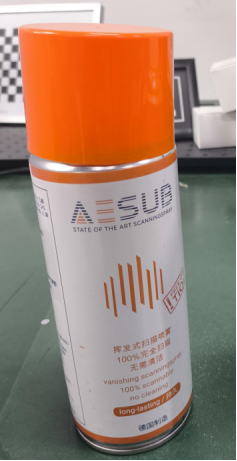

- AESUB-orange: This spray is designed to evaporate automatically after use. It creates an even, thin layer that won’t leave residue behind — minimizing measurement errors.

- DPT-5: This one doesn’t evaporate by itself. If you don’t apply it carefully, you can easily get spots that are too thick or too thin, which throws off your scan results.

- REFLECON: This new-generation spray provides high reflectivity, improving contrast for your scanner. But be careful — apply too much and you’ll still introduce deviations in your data.

The Right Technique Makes All the Difference

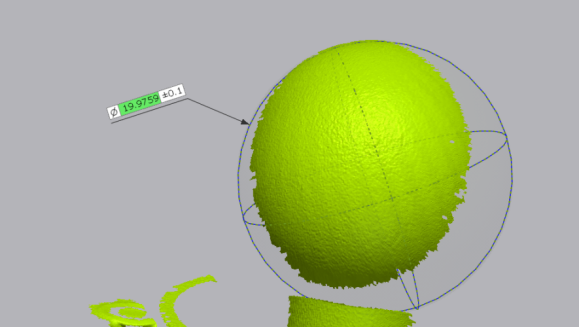

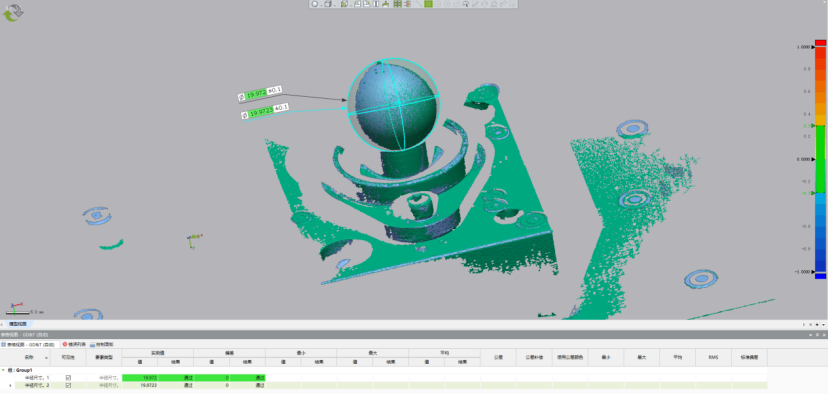

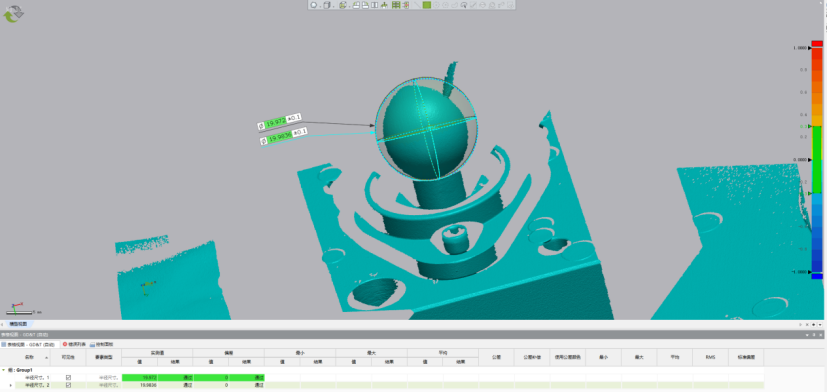

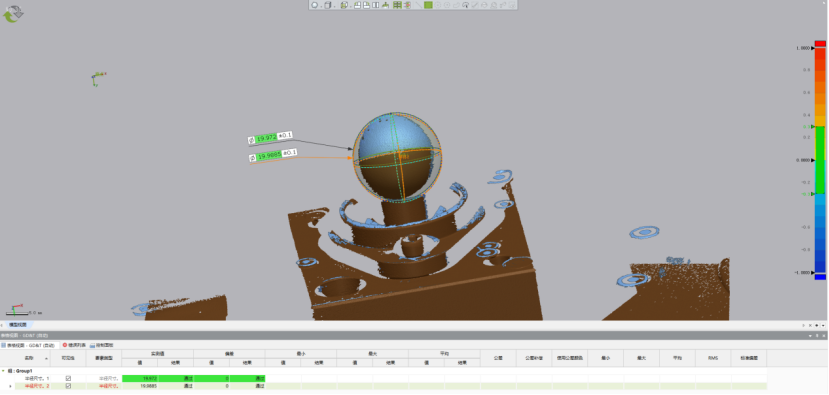

It’s not just about which spray you choose — it’s how you use it. In testing, DPT-5 showed larger deviations when applied too heavily. On the flip side, AESUB-orange delivered consistently low deviation when sprayed correctly: its measured diameter deviation stayed within just 0.0063 mm! REFLECON also performed well but needs good control to keep the coating thin and even.

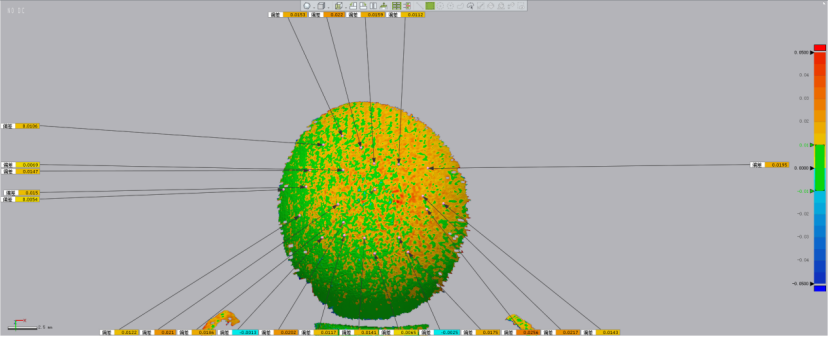

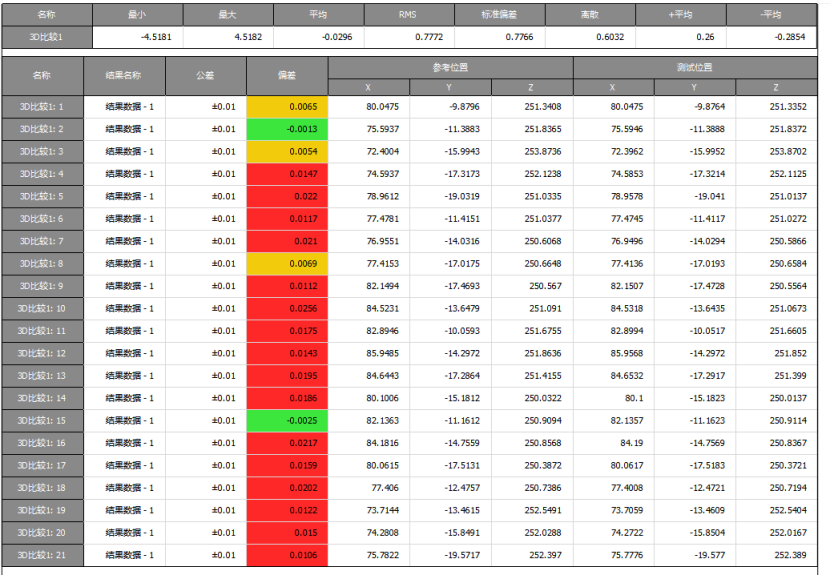

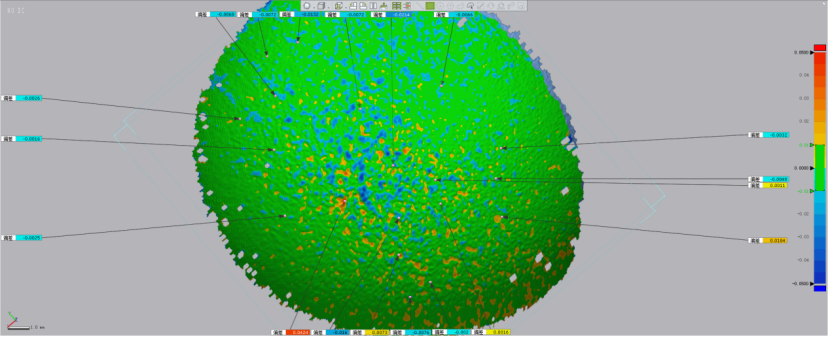

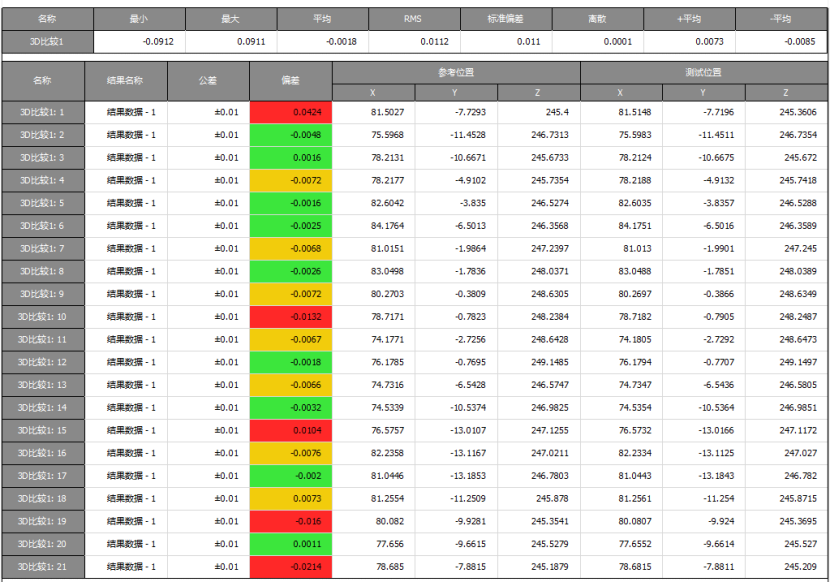

Real-World Data Tells the Story

In practical tests with standard spheres and gauge blocks:

- AESUB-orange consistently produced the smallest measurement errors (around 0.0028 mm to 0.0063 mm).

- DPT-5 had higher deviations (up to 0.0226 mm).

- REFLECON landed in the middle, offering reliable 3D scanner accuracy if applied carefully.

This clearly shows that the type of scanning spray — and your spraying process — can make a measurable difference in how precise your 3D models turn out.

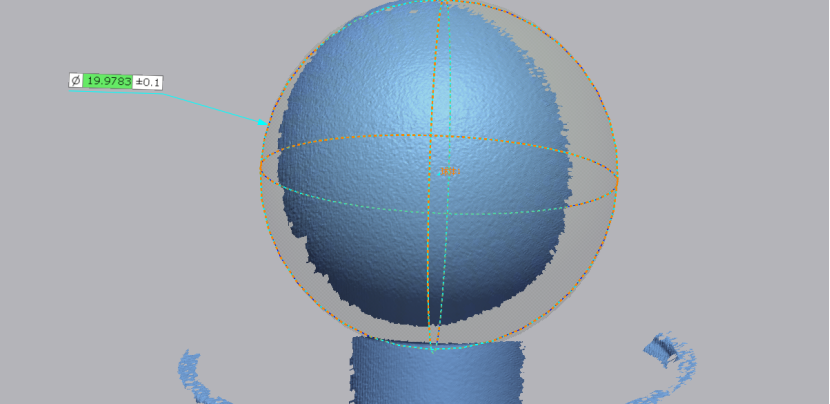

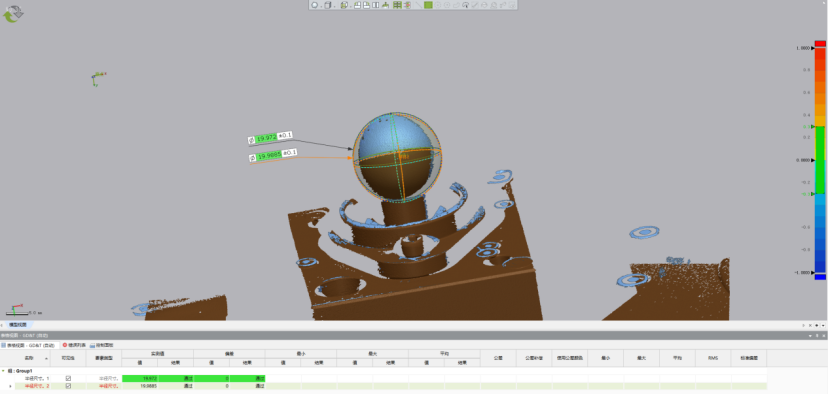

| Sample | AESUB_1 | AESUB_2 | AESUB_3 | DPT-5_1 | DPT-5_2 | DPT-5_3 |

|---|---|---|---|---|---|---|

| Diameter (mm) | 19.9783 | 19.9759 | 19.9723 | 19.9836 | 19.9885 | 19.9946 |

| Deviation (mm) | 0.0063 | 0.0039 | 0.0003 | 0.0116 | 0.0165 | 0.0226 |

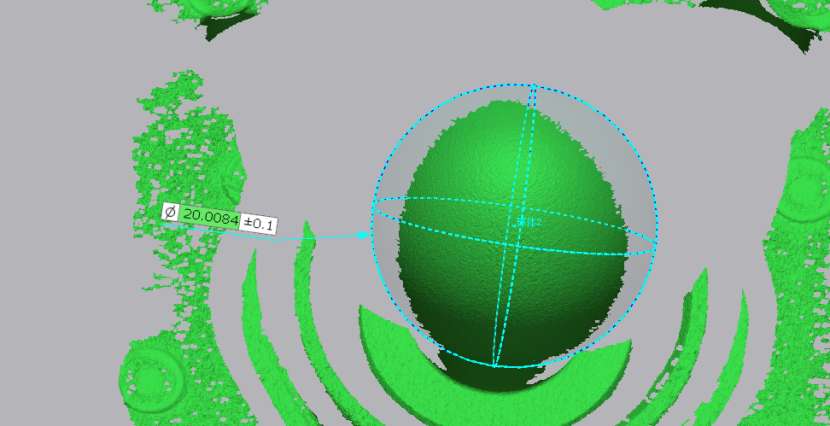

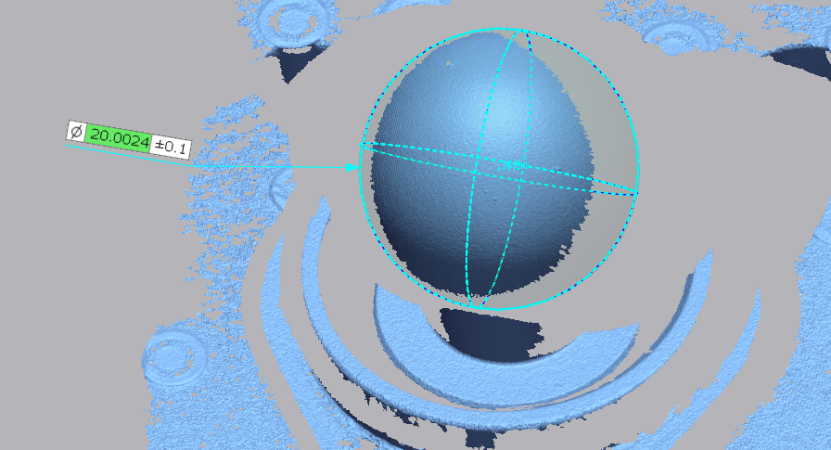

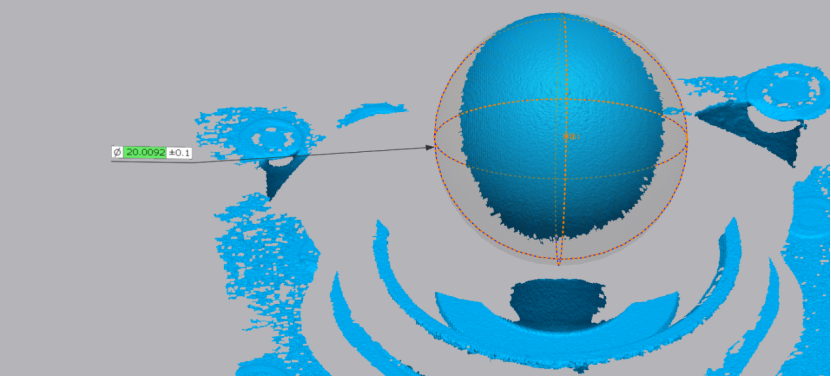

| Sample | REFLECON_1 | REFLECON_2 | REFLECON_3 |

|---|---|---|---|

| Diameter (mm) | 20.0084 | 20.0024 | 20.0092 |

| Deviation (mm) | 0.0069 | 0.0060 | 0.0078 |

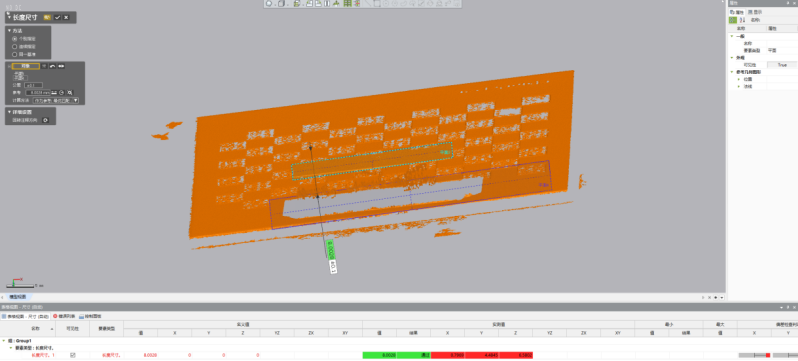

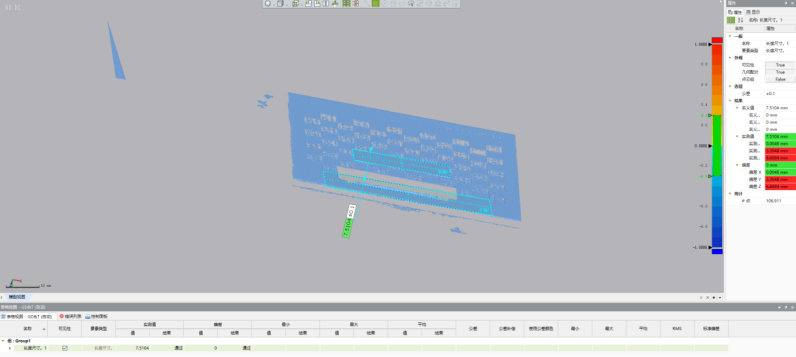

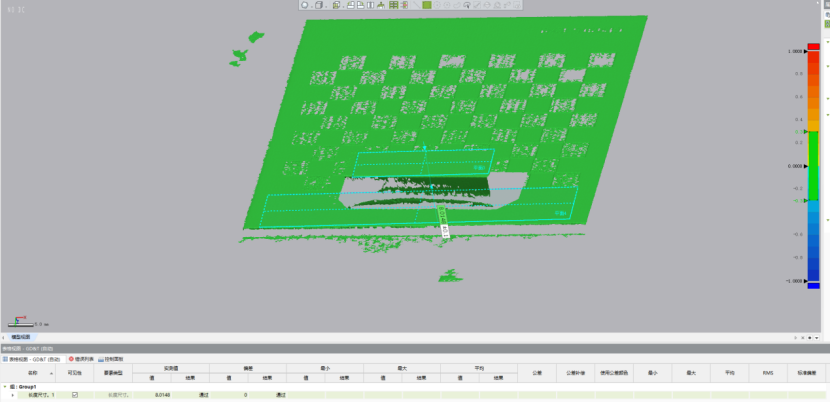

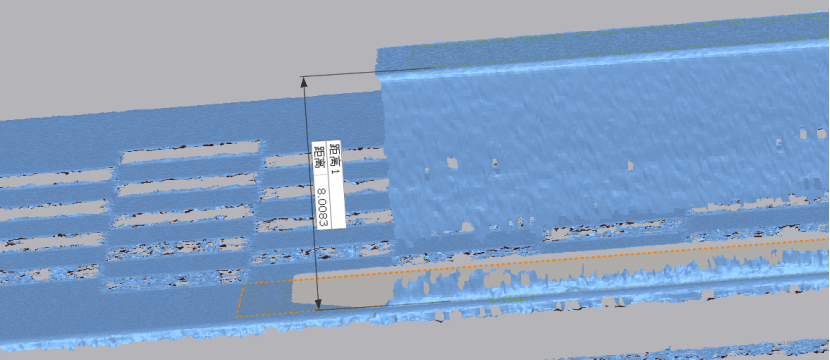

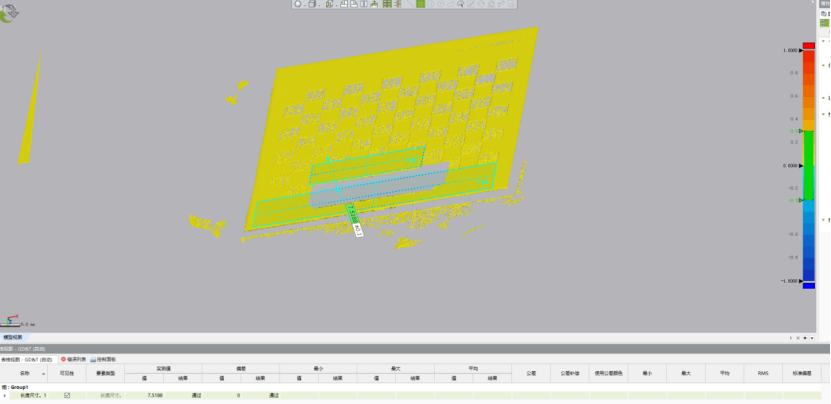

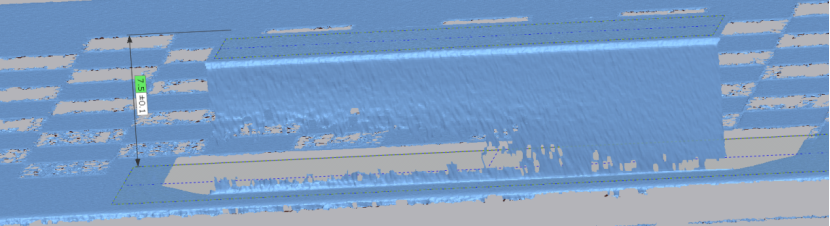

Gauge Block Size Comparison

When it comes to measuring gauge blocks, the impact of different 3D scanning sprays is just as clear. For an 8.0 mm gauge block coated with AESUB-orange, the deviation was only 0.0028 mm. In contrast, using DPT-5 led to a deviation of up to 0.0148 mm. The REFLECON spray landed in between, with a deviation of 0.0083 mm for the same gauge block.

The same trend appeared with the 7.5 mm gauge block — AESUB-orange consistently delivered the smallest measurement errors, DPT-5 showed larger deviations, and REFLECON stayed in the middle range.

This shows that the type of scanning spray you choose can significantly affect your industrial 3D scanner’s accuracy when measuring objects of different sizes. Under the right conditions, REFLECON can also provide impressive 3D scanner accuracy, especially for specific high-precision scenarios.

| Gauge Block | AESUB-ORANGE | DPT-5 | REFLECON |

|---|---|---|---|

| 8.0 量块 长度 (mm) | 8.0028 | 8.0148 | 8.0083 |

| 8.0 量块 偏差 (mm) | 0.0028 | 0.0148 | 0.0083 |

| 7.5 量块 长度 (mm) | 7.5104 | 7.5188 | 7.5141 |

| 7.5 量块 偏差 (mm) | 0.0104 | 0.0188 | 0.0141 |

After comparing the sprayed gauge blocks:

8.0mm

7.5mm

8.0mm

7.5mm

Choose Smart — Scan Better

So, if you’re looking to get the best out of your industrial 3D scanner, don’t overlook the scanning spray! Pick the right one for your needs, master the right technique, and you’ll unlock better data, better models, and fewer headaches.

At Xiangxi Smart, we’re committed to pushing 3D scanning technology forward — helping you achieve top-notch accuracy and efficiency for every project.

👉 Want to learn more about our industrial 3D scanners and how to boost your scanning precision? Visit our website, follow us on our social channels, and reach out to our team anytime. Let’s shape the future of 3D scanning together!

Subscribe Our Channel

XX-3DTECH (Xiangxi Intelligent technology) is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.