How to Calibrate Your 3D Scanner for Maximum Accuracy: A Practical Guide

When it comes to 3D scanning, accuracy is everything. One of the most effective tools for boosting your 3D scanner accuracy is a calibrated plate. If you want sharper 3D models and more reliable data, knowing how to properly calibrate your optical 3D scanner is a must.

Step 1: Get Ready Before Calibration

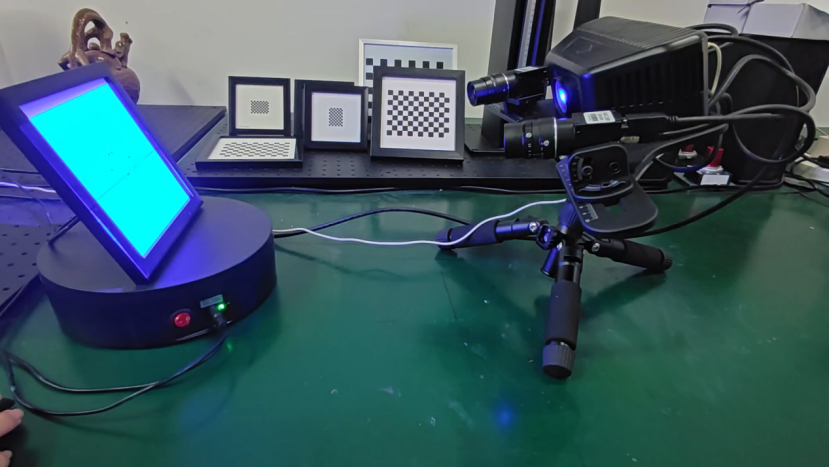

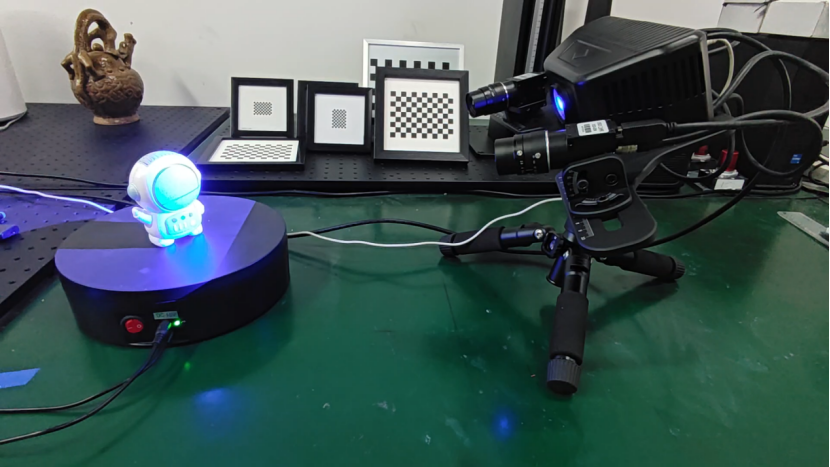

First things first — make sure you have a reliable 3D scanner. At Xiangxi Intelligent, our scanners are known for high precision and easy operation. Before calibration, connect your scanner to your computer and install the right calibration software. Always use a clean, scratch-free calibrated plate — even a small stain can throw off your results and lower your 3D scanning accuracy.

Also, check your lighting conditions. Avoid strong direct light or overly dark environments. Stable lighting helps your scanner reach its best performance during calibration.

Step 2: Start the Calibration Process

Place the Calibrated Plate

Position the calibrated plate within your scanner’s field of view. Keep it flat and directly facing the camera. This setup is the foundation of accurate 3D scanning. Follow your software’s instructions to adjust the angle — capture the plate from multiple directions to collect diverse data points. This step alone will significantly improve your optical 3D scanner’s accuracy.

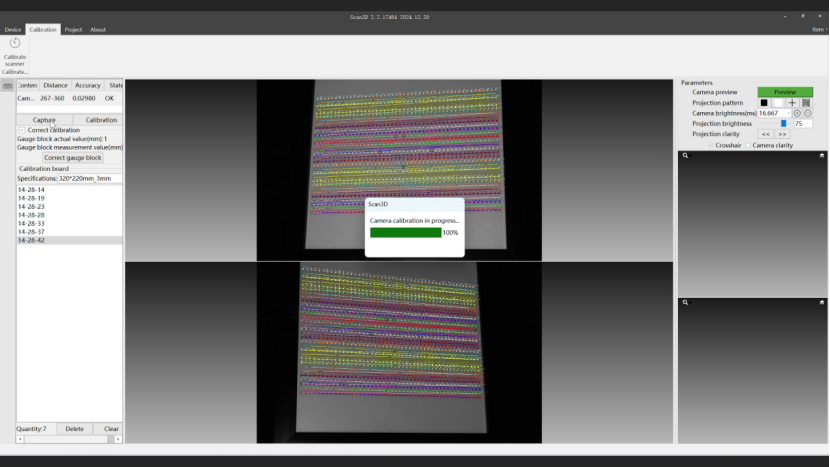

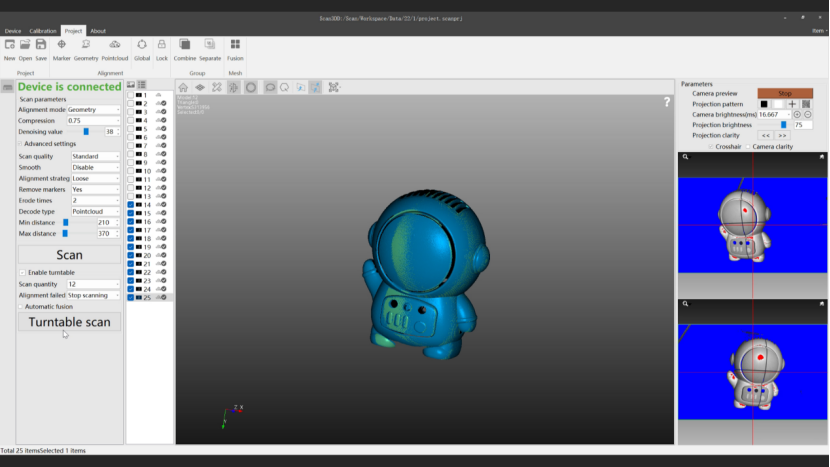

Begin Capturing Data

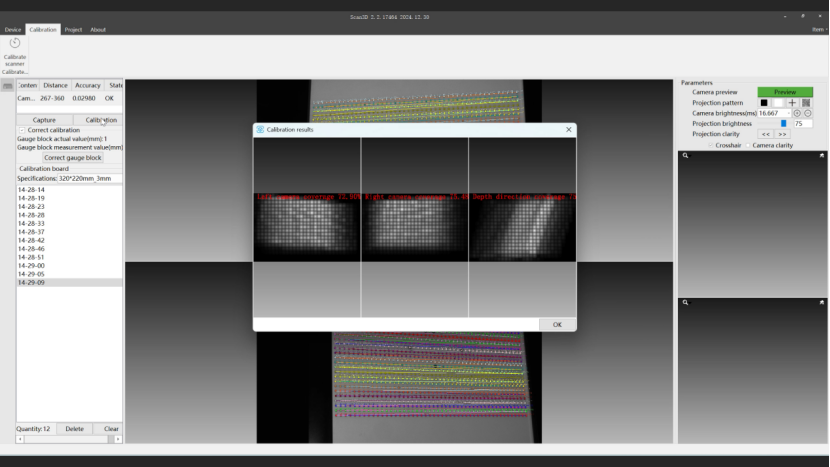

During calibration, your scanner detects special points on the calibrated plate. These points help the system calculate both internal and external camera parameters — a vital step for pinpointing an object’s position and pose in 3D space. You’ll usually need to capture at least eight sets of images from different positions. The software will then auto-calculate the necessary parameters to fine-tune your 3D scanner accuracy.

Confirm and Save

Once your software shows coverage above 65%, hit confirm. That’s it — your scanner is now calibrated and ready to deliver precise results.

Step 3: Test and Apply

After calibration, do a quick test scan to check the results. If your scan looks off, repeat the calibration — check your plate’s placement and camera angles. These details can make or break your final 3D scan.

A properly calibrated scanner gives you cleaner, more detailed 3D models, which is crucial for industries that rely on accurate 3D scanning and modeling.

At the end of the day, using a calibrated plate is the smartest way to keep your 3D scanner accuracy high and your 3D models reliable. Careful prep, precise calibration, and proper validation — that’s the secret to getting the most out of your optical 3D scanner.

Got questions about calibration or 3D modeling? We’d love to help. Visit our website, check out our solutions, and feel free to get in touch — we’re here to support your 3D scanning success!

Subscribe Our Channel

XX-3DTECH (Xiangxi Intelligent technology) is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.