Why 3D Scanners Need Calibration — and How It Transforms Accuracy

In today’s fast-moving digital world, 3D scanning has become the backbone of modern industries — from product design and quality inspection to cultural preservation and medical modeling.

Whether you’re capturing complex mechanical parts or delicate historical artifacts, the accuracy of your data defines the quality of your 3D model.

But here’s the truth: no matter how advanced your 3D scanner is, without proper calibration, you’ll never get truly accurate results. Even the best hardware depends on fine-tuned alignment and calibration to deliver precision at every level.

Let’s explore why calibration matters, and how a reliable and high-precision calibrated plates can dramatically improve your 3D modeling accuracy.

Calibration: The Heart of 3D Scanner Accuracy

Calibration is the fine-tuning process that ensures your 3D scanner captures the world exactly as it is.

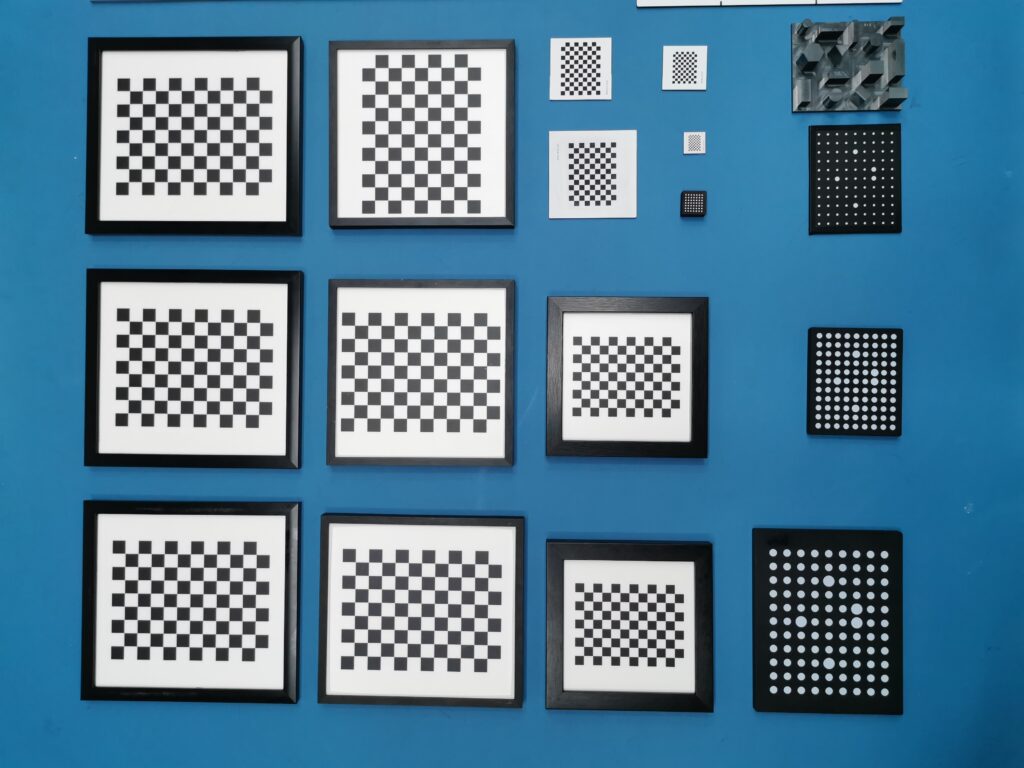

Using a calibration board — usually printed with checkerboard or dot patterns — the scanner adjusts its optical parameters to interpret distance, shape, and position correctly in 3D space.

Proper calibration directly affects the accuracy, consistency, and repeatability of your 3D scanning results. Even small environmental changes — such as lighting variation, lens vibration, or temperature drift — can cause subtle errors in depth calculation. Regular calibration compensates for these deviations, keeping your system stable and reliable. It also aligns multiple cameras or projectors within the scanner, ensuring that every frame is perfectly synchronized. Whether you’re scanning tiny jewelry or large industrial parts, correct calibration guarantees that your digital models truly reflect real-world geometry, delivering professional-level precision for design, inspection, or reverse engineering.

You might think your 3D scanner was “factory-calibrated,” but over time, external factors like lighting changes, mechanical vibration, or natural hardware drift can reduce accuracy. Even small environmental variations — like a slight temperature shift — can affect your scanner’s optical system. That’s why regular calibration using professional calibrated plates is essential.

A properly calibrated scanner solves common issues like:

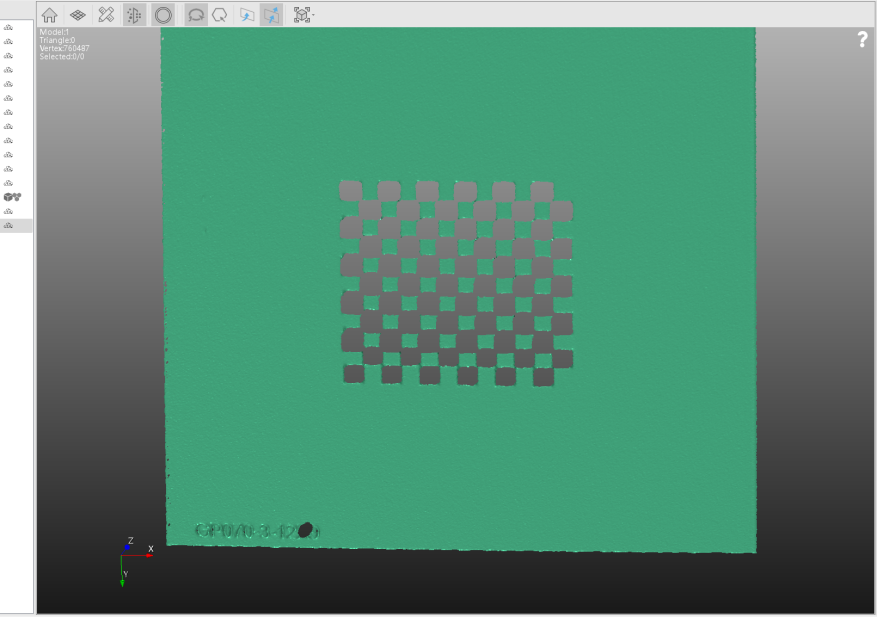

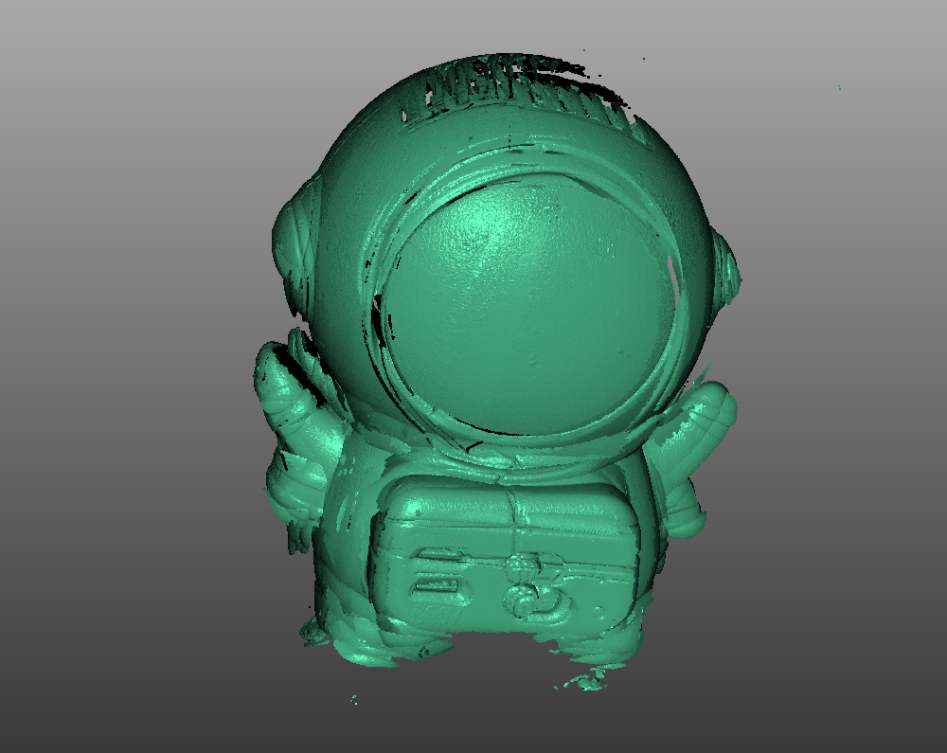

Distorted geometry — circles that look like ovals or curved lines that should be straight.

Alignment errors — multi-angle scans that don’t stitch perfectly, causing ghosting or gaps.

Inconsistent results — repeated scans that never quite match up.

When done right, calibration transforms your scanner from “good enough” to “precisely perfect,” giving you true-to-scale models and saving hours in post-processing corrections.

How to Properly Calibrate a 3D Scanner

Getting consistent accuracy isn’t about luck — it’s about process.

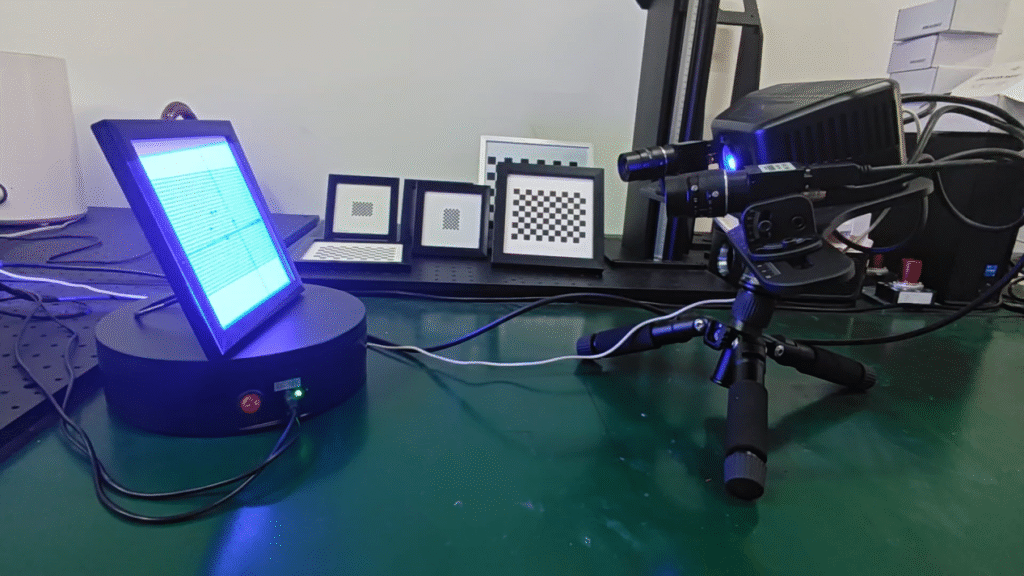

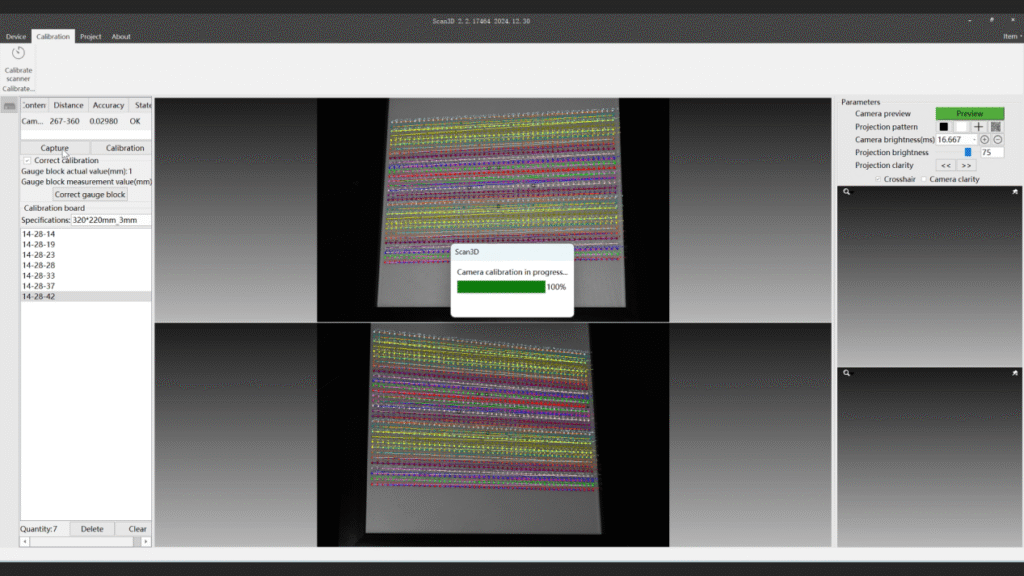

Step 1: Prepare your setup

Connect your scanner to the computer and open your calibration software. Clean your calibration board carefully — even small dust or fingerprints can affect accuracy. Keep lighting even, without glare or shadows, to ensure stable imaging.

Step 2: Position the calibration board

Place the board within the scanner’s field of view, perfectly flat and steady. Capture images from multiple angles — front, side, diagonal — to gather complete geometric data.

Tip: avoid moving the scanner too quickly; a stable setup gives better point accuracy.

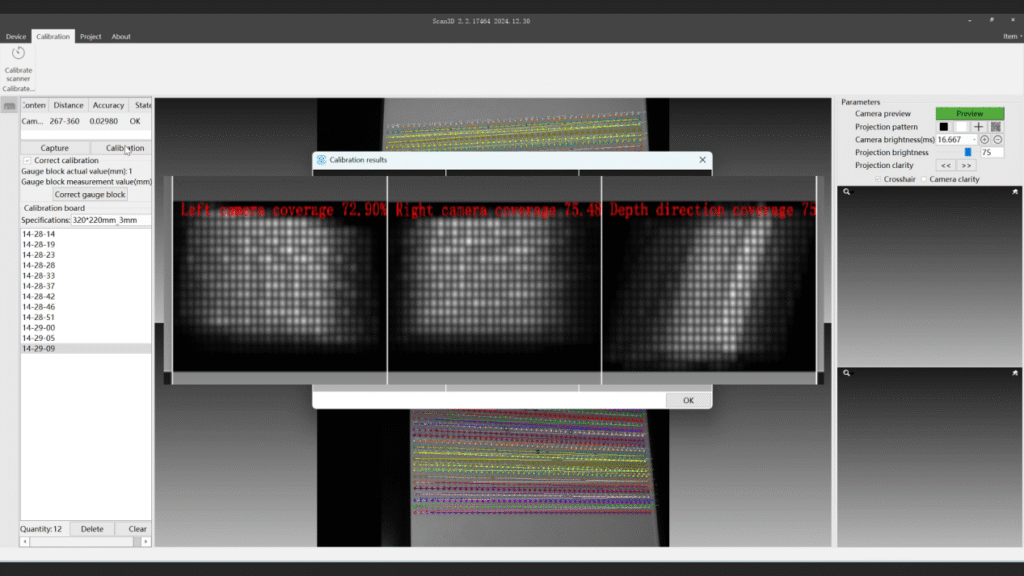

Test, Verify, and Enjoy Sharper Results

After calibration, perform a quick test scan to verify the outcome.

If you notice any distortion, repeat the process — minor adjustments to your calibration board distance or tilt often make a huge difference.

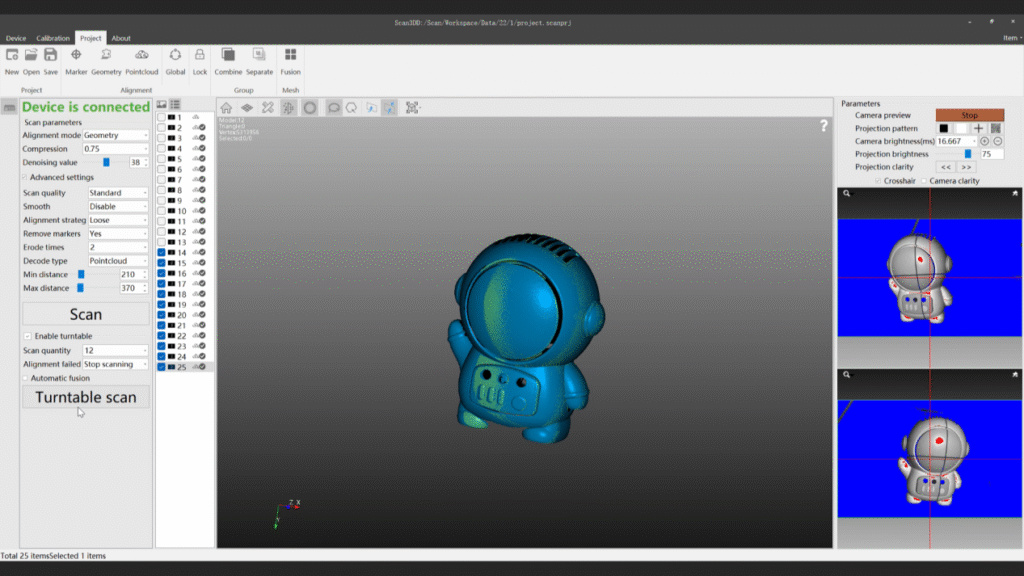

Once properly calibrated, your scanner produces crisp, dimensionally accurate 3D models with better surface detail and smoother edges. This accuracy is critical in industries like automotive, aerospace, and cultural preservation, where every millimeter counts.

Simply put, good calibration means every scan is faster, cleaner, and more reliable — saving time, improving repeatability, and giving you confidence in every capture.

Conclusion: Precision Starts with Calibration

Accurate scanning starts long before you press “scan.”

By following a structured calibration process — and using quality calibrated plates — you ensure every project achieves professional-level precision.

So, if you’ve ever wondered why your 3D scans don’t look perfect, the answer is often simple: calibration is the foundation of every flawless model.

Want to take your 3D scanner performance to the next level?

Visit our web to learn more about advanced calibrated plates, and professional-grade scanning systems.

Let’s unlock sharper models, faster workflows, and better results — together.