Practical 3D Scanning Tips to Help You Get Sharper, Stunning Models and Lightning-Fast Results

In today’s digital era, a 3D scanner is one of the most powerful tools for capturing precise shapes and details. Whether you’re working in industrial design, cultural preservation, or film production, mastering 3D scanning can dramatically improve your modeling efficiency.

But if you’re new to using an optical 3D scanner, you might face challenges like blurry images, overexposure, or unstable objects during the scanning process. Don’t worry—this guide shares practical 3D scanning tips to help you fix these common problems and achieve professional-quality results.

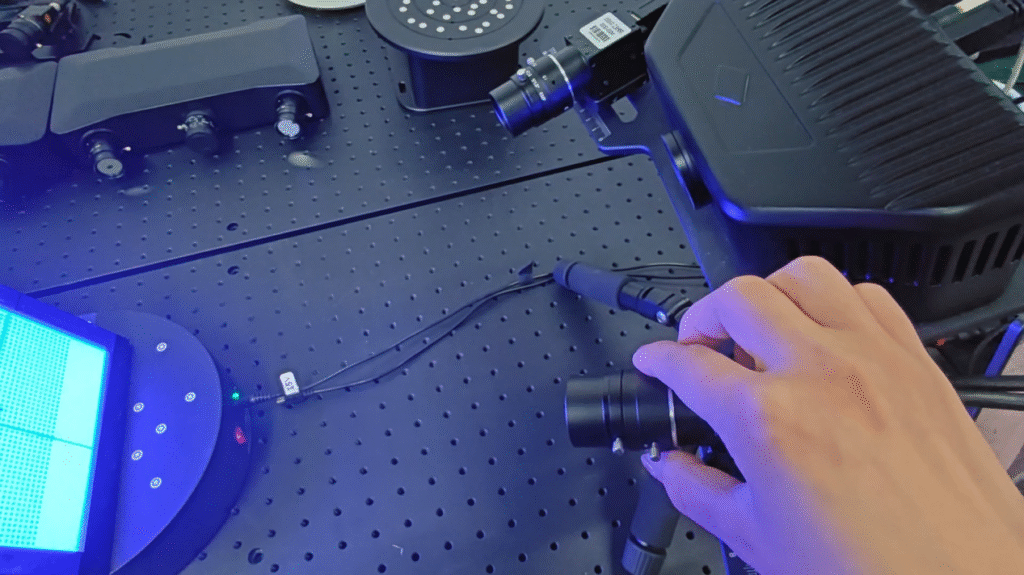

Blurry Images: Focus on Clarity

When using an optical 3D scanner, image clarity is everything. Many beginners forget to adjust the focus properly, which leads to unclear scans and inaccurate models.

Before you start 3D scanning, align your scanner with the object and fine-tune the focus until every detail is sharp. At Xiangxi Intelligent, our high-precision scanners come with easy focus adjustment to help you capture crisp, accurate data.

👉Remember: clear images mean precise 3D models

Overexposure: Master the Light

Overexposure is another common issue during scanning. When your aperture is too wide or the surface is highly reflective, you may lose texture detail. To prevent this, balance the lighting and adjust your aperture before scanning.

Our optical 3D scanners feature intelligent exposure control that automatically adapts to different surfaces and lighting conditions—so you can achieve consistent and accurate results every time. This is one of the most valuable 3D scanning tips for achieving perfect color and texture reproduction.

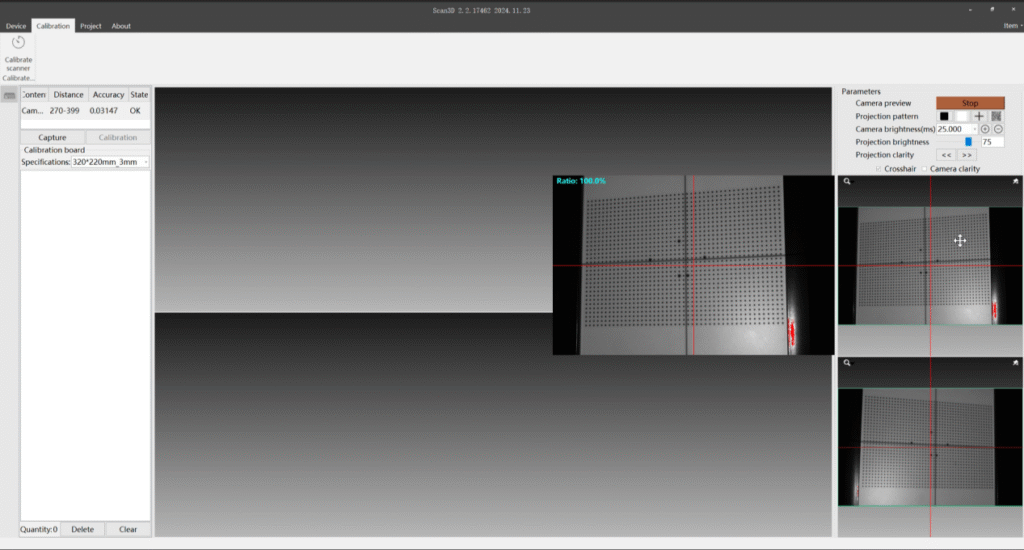

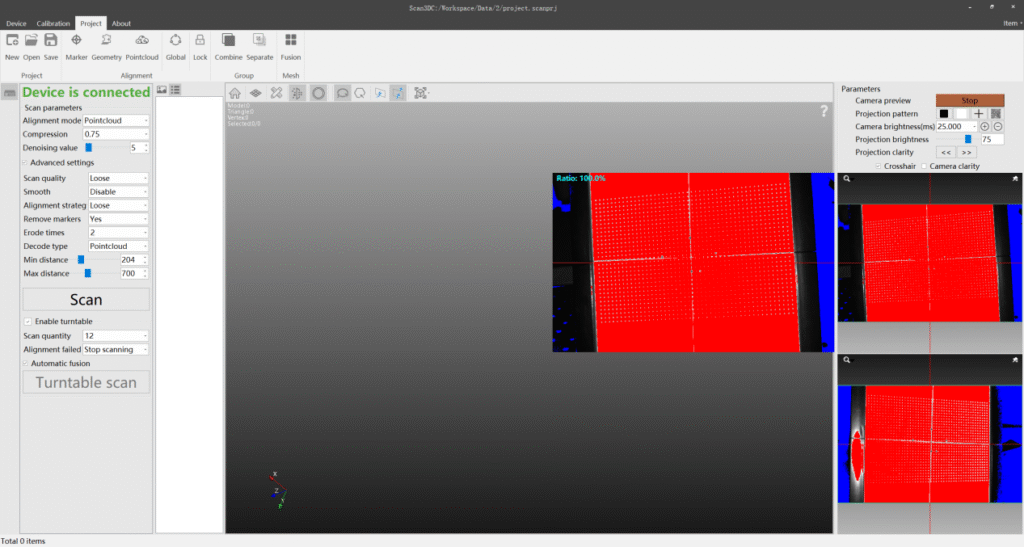

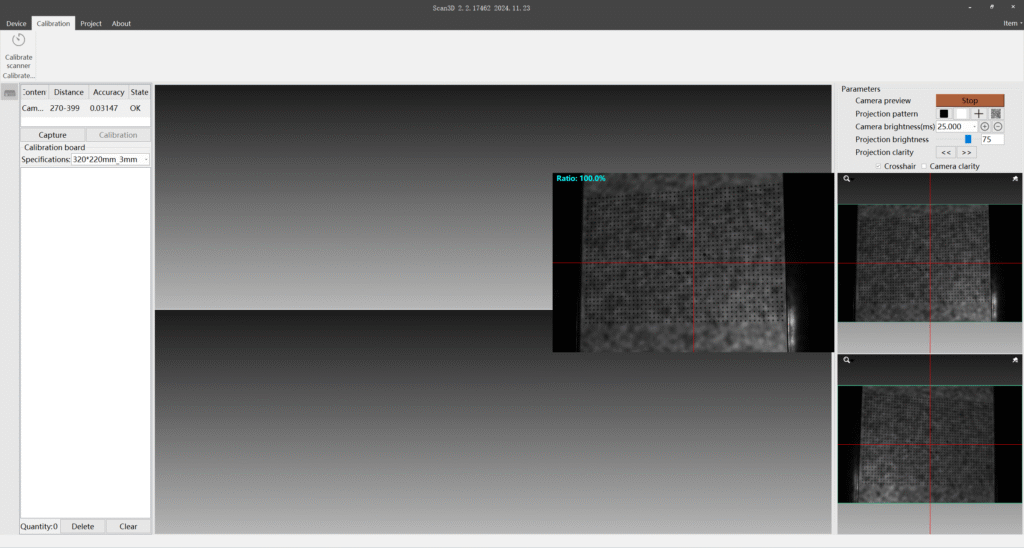

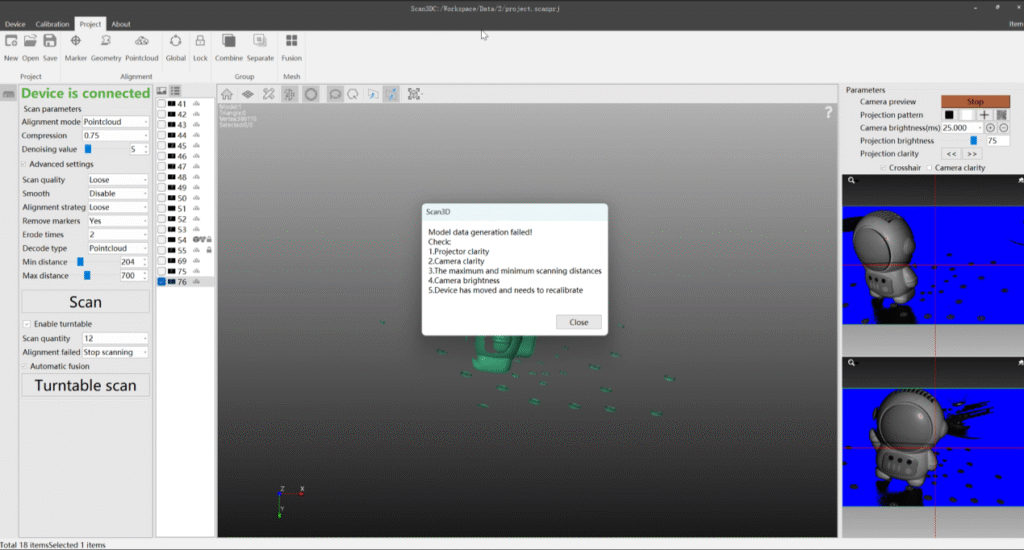

Projector Blur: Calibrate for Precision

If your projected pattern appears fuzzy, your scan data will suffer. Projector blur happens when the projector’s focus or position is off. Always check projection clarity before scanning.

With Xiangxi Intelligent’s calibration software, you can fine-tune the projector of your 3D scanner for crystal-clear projection. Precision projection is essential for high-quality results.

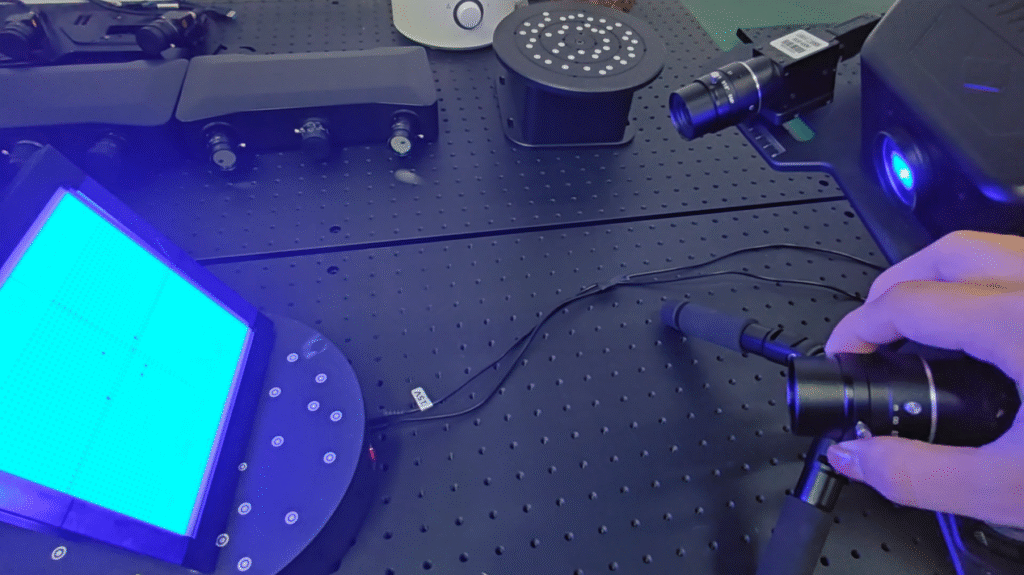

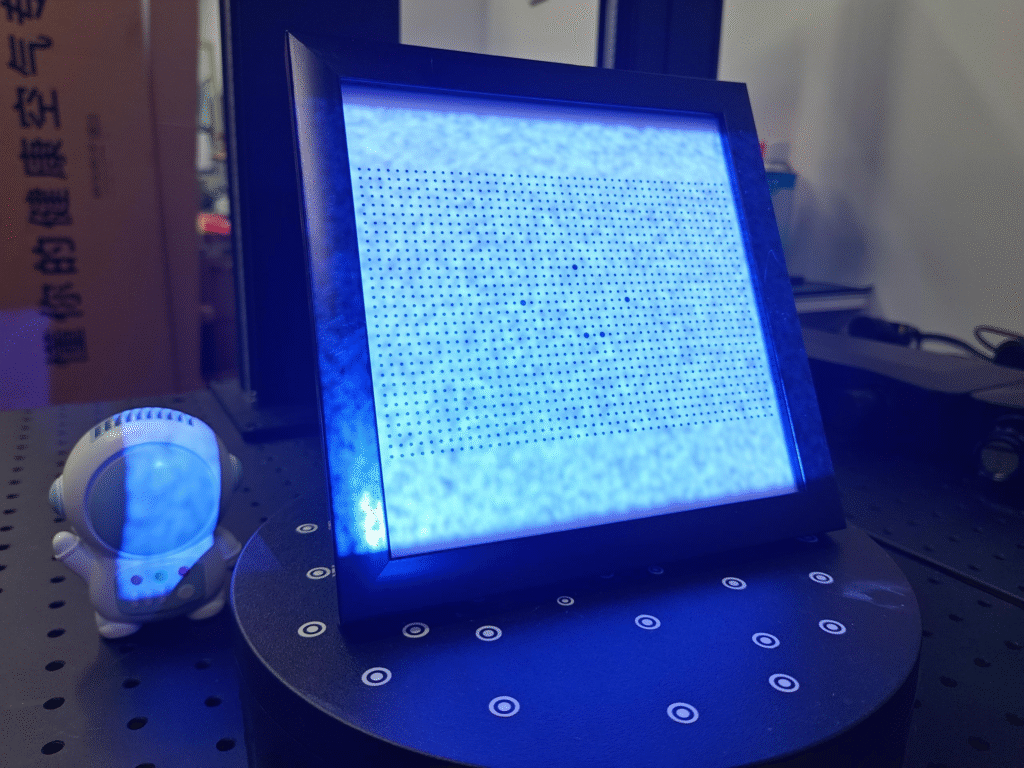

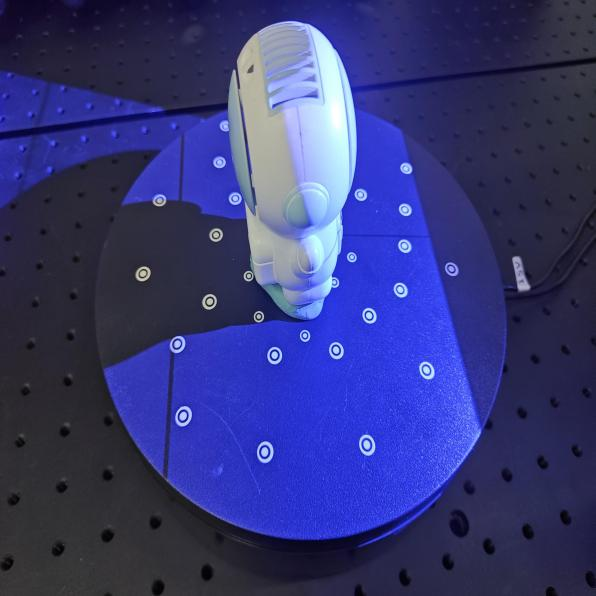

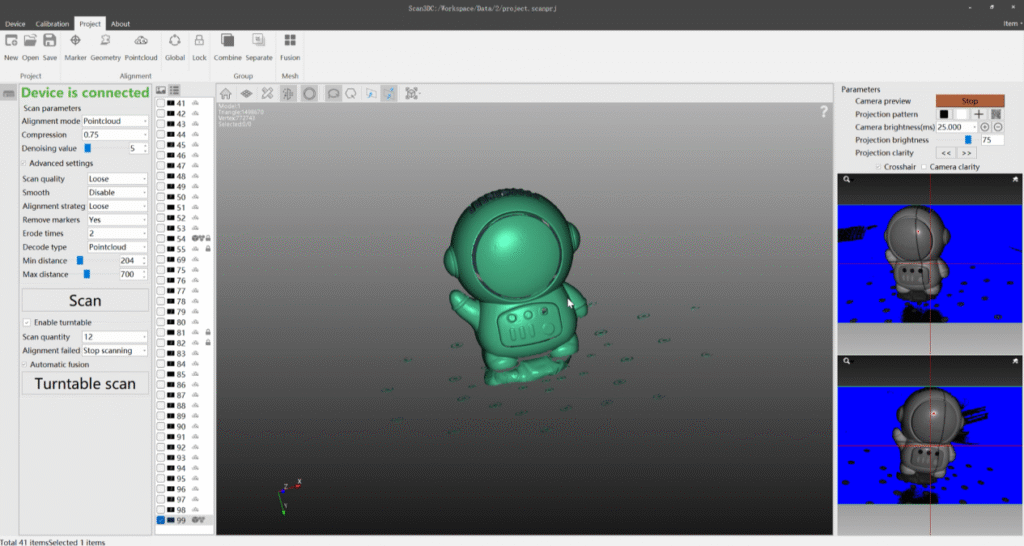

Object Movement: Keep It Still

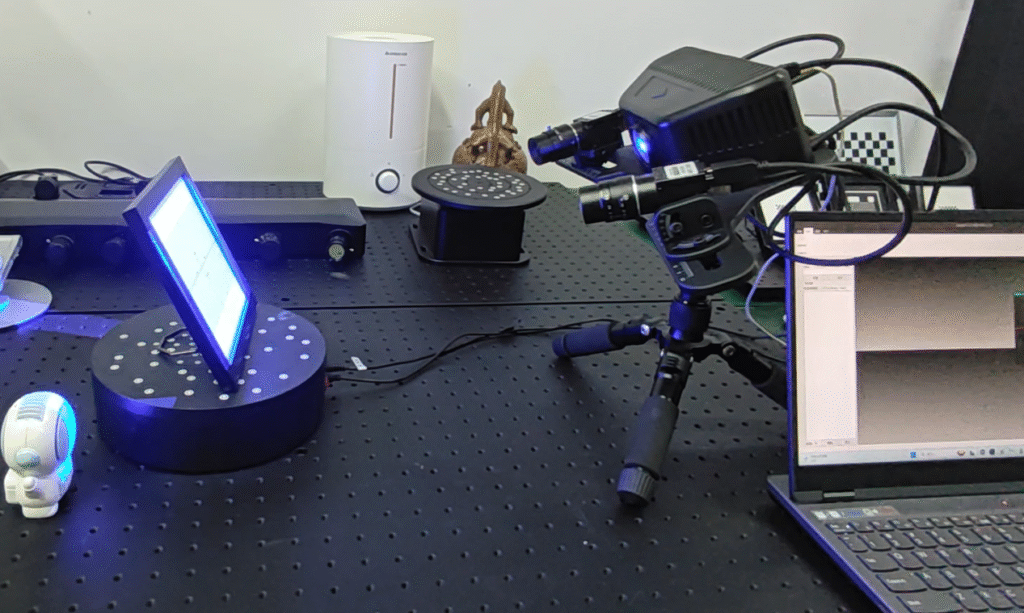

A stable object ensures a successful 3D scanning session. Movement during scanning can lead to misaligned point clouds or incomplete meshes. To fix this, secure your object using adhesive putty or a rotating turntable.

Our optical 3D scanners include stable platforms and auxiliary fixtures that prevent vibration or displacement. Among all scanning tips, maintaining stability is one of the easiest ways to improve accuracy.

Ready to Scan? Let the 3D Modeling Begin

By understanding and fixing these issues, you’ll make your 3D scanning workflow smoother and your 3D models more detailed. Avoiding simple mistakes—like misfocus or overexposure—can save you hours of rework. In addition, paying attention to lighting conditions, surface preparation, and scanner positioning can dramatically improve your scan accuracy. Always take time to calibrate your device properly and double-check each setup before starting a new project. Consistency in your workflow not only reduces scanning errors but also helps you build reliable, high-quality models faster. The more you refine your scanning process, the easier it becomes to achieve professional, repeatable results every time.

If you want to explore more professional 3D scanning tips or see how Xiangxi Intelligent’s Optical 3D Scanners can improve your workflow,

visit our official website to learn more or contact our team for expert support.

Let’s make your next 3D scan your best one yet!

XX-3DTECH (Xiangxi Intelligent technology) is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.