Transforming Reverse Engineering with High-Accuracy 3D Scanning Alignment Techniques

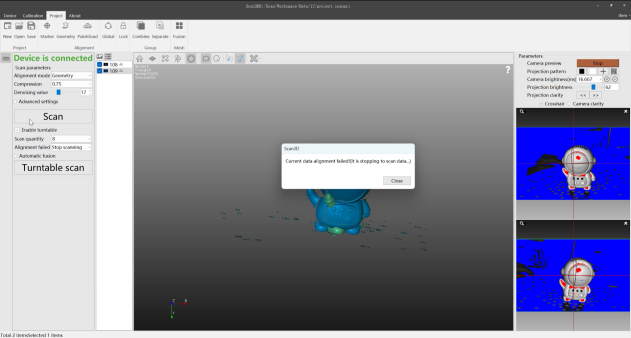

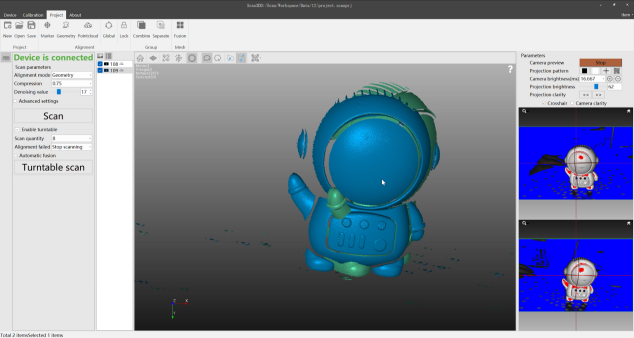

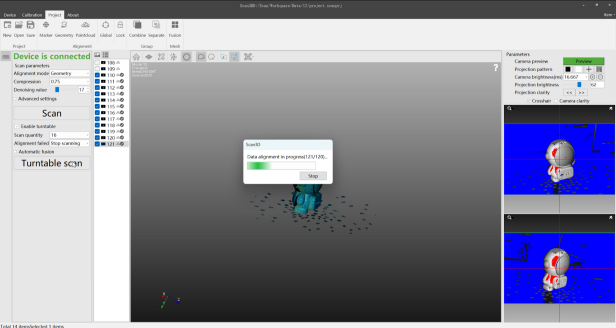

If you’ve ever struggled with 3D scanning alignment failures during 3D modeling, you’re not alone. Whether you’re scanning industrial parts for reverse engineering or intricate sculptures, misaligned data can tank your efficiency and accuracy. But don’t worry—with the right strategies (and a high-precision scanner like Xiangxi Intelligent’s), you can turn this roadblock into a smooth path. Let’s dive into the root causes of alignment failures and actionable solutions to level up your scanning game.

Three Alignment Modes to Save Your 3D Modeling Projects

Xiangxi Intelligent’s high-res camera captures markers instantly – the must-know scanning tips for glossy industrial parts.

- Feature Alignment: Perfect for Complex Objects

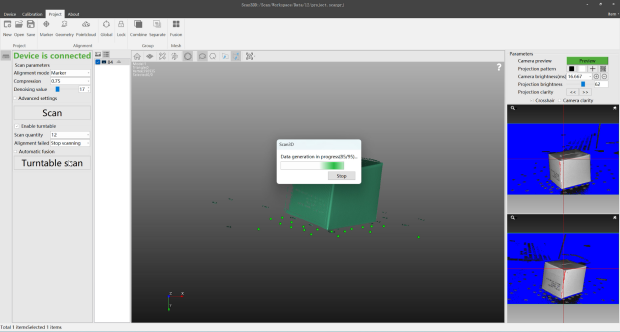

If your object has rich surface textures (e.g., mechanical parts or carved artworks), enable Feature Alignment. Perform multiple small-angle scans to ensure data overlap, boosting algorithm success rates. The scanner’s AI automatically detects edges and holes, slashing manual effort—ideal for reverse engineering - Marker Alignment: Tackle Featureless Surfaces

For symmetrical workpieces or smooth curved surfaces, apply markers randomly. The scanner’s high-res camera captures coordinates instantly, even in low light—perfect for glossy objects common in 3D modeling. - Hybrid Mode: Balance Speed & Accuracy

Scanning large, intricate objects? Combine Feature and Marker Alignment. Activate Smart Stitch to auto-blend data seamlessly—a game-changer for industrial scanning projects requiring precision.

Pro Tips to Boost Efficiency

- Optimize Your Scanning Environment

Use uniform lighting and a tripod to stabilize your scanner, ensuring consistency for modeling.

- Tweak Parameters Like a Pro

Adjust resolution based on project needs – one of the most underrated scanning tips for balancing speed and detail(e.g., reverse engineering components), lower res for speed on large objects. - Fix Tiny Errors in Software

Use the “Manual Fine-Tuning” tool to correct misalignments—critical for flawless modeling results.

The success of scanning and modeling hinges not just on your scanner’s specs, but on mastering alignment techniques. By switching strategies, fine-tuning parameters, and leveraging software fixes, you’ll slash alignment failures and supercharge efficiency—whether you’re tackling industrial reverse engineering or creative projects. By combining these scanning tips with precision tools, you’ll eliminate alignment headaches in modeling and reverse engineering. Ready to scan smarter?

Subscribe Our Channel

Xiangxi Intelligent technology is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.